Geared Elevators

Engineered for Mid-Rise Performance and Lifecycle Efficiency

Geared traction elevators with a machine room (MR) offer a balanced solution for mid-rise applications where moderate speeds, robust lifting capacity, and ease of serviceability are essential. Designed for long-term performance and flexible integration, these systems remain a standard for commercial, institutional, and mixed-use developments.

System Overview

Geared traction elevators utilize a reduction gearbox coupled with a high-speed AC motor to drive the hoisting sheave. The system is housed in a dedicated machine room located directly above the hoistway, allowing for straight forward access to mechanical and control components.

Typical Specifications:

Travel Speed: 0.50 m/s 1.5 m/s

Maximum Travel Height: ~ 30 meters

Capacity Range: 408 kg – 3,500 kg

Drive Types: AC VVVF (Variable Voltage Variable Frequency)

Duty Cycles: Optimized for medium- to high-traffic environments

Key Features:

Reliable and proven technology

Smooth ride quality

Cost-effective for medium-duty applications

Easier to maintain due to accessible machine room

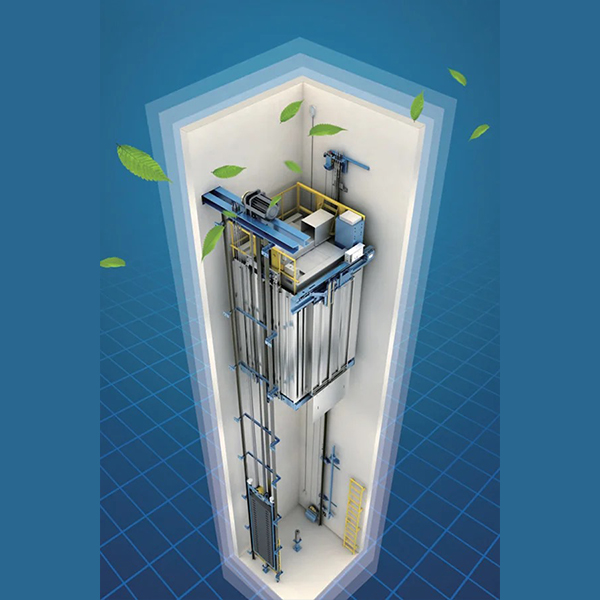

Gearless Elevators

Gearless Elevators (Machine Room-Less - MRL) are a modern type of elevator system that combines the advantages of gearless traction technology with a machine room-less design, making them an efficient and space-saving solution for mid- to high-rise buildings. Here's a breakdown of what this means and why it's important:

Gearless elevators use a direct drive system where the motor is directly connected to the sheave (pulley), eliminating the need for gears. This results in:

In traditional elevators, a separate machine room is required above or beside the elevator shaft to house the motor and control equipment. MRL elevators integrate this equipment within the hoistway itself, usually at the top of the shaft.

Benefits of MRL:

Saves up to 25% of building space

Lower construction costs (no separate machine room)

Easier installation in existing buildings (retrofits)

More energy efficient

Gearless MRL Elevators – Key Features

| Feature | Benefit |

|---|---|

| Compact Gearless Motor | High efficiency, small footprint |

| No Machine Room | Frees up valuable floor space |

| VFD (Variable Frequency Drive) | Smooth acceleration and deceleration |

| Reduced Noise & Vibration | Ideal for residential and commercial spaces |

Typical Applications

Mid-rise to high-rise commercial buildings

Residential towers

Hotels

Hospitals

Retrofits in existing buildings where space is limited

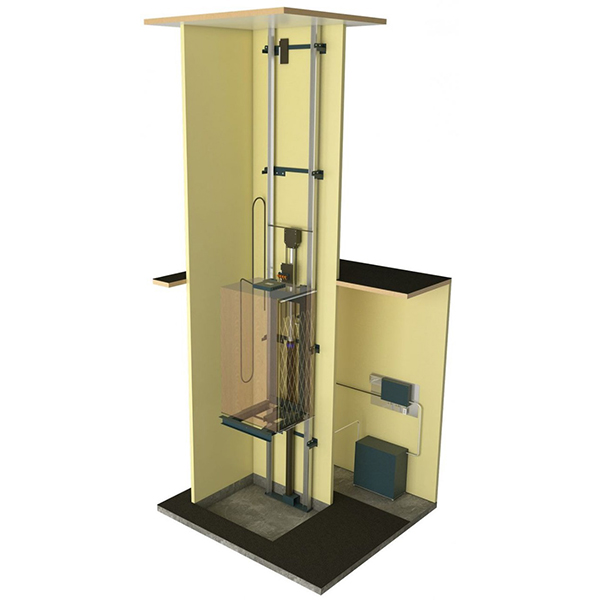

Hydraulic Elevator Systems

Hydraulic elevators are powered by a fluid-driven piston mounted inside a cylinder. Unlike traction elevators, they don’t require an overhead machine room, making them ideal for buildings with limited space or specific architectural needs.

Key Advantages:

Space Efficiency: No need for an overhead hoistway — machine room can be located at the basement or ground floor level.

Smooth Ride Quality: Quiet and vibration-free operation ideal for residential and commercial use.

High Load Capacity: Suitable for freight elevators or buildings with higher weight requirements.

Low Maintenance: Fewer moving parts mean lower maintenance costs and less downtime.

Our Hydraulic Elevator Features

Available in single, dual, or telescopic piston configurations

Automatic or manual doors with modern finishes

Emergency lowering and backup power systems